|

|

|

| |

Jar

Mill Jar

Mill

|

|

| |

|

| MIKRONS®

Jar mill updates and improves material processing

through a simple yet efficient contamination free

grinding process. They are designed specifically

for applications where space is at premium. Available

in single and multiple tier models and with roll

length of 300, 600, 900 &1200 mm. |

| |

|

|

|

| The

unique operating characteristics of our Jar mill

satisfy the most stringent requirements of the chemical,

ink, paint, plastics, food and pharmaceutical industries.

Our jar mills are ideal for R&D, small production

runs, for grinding laboratory or high-purity samples.

These mills provide quiet and smooth operation.

|

| |

- Single or multi-tier

design, two or three jars per tier

- No cross-contamination

between samples

- Grinding jars

and media in material to suit your application

- Each tier accepts

jars measuring 2 to 10" in diameter.

- Easily adjustable

rollers and brackets to accommodate different

jars of various diameter.

- The speed can

be varied from 10 to 260 rpm using VFD

- Each tier has

a maximum capacity of 13 kg. Two-tier mills

rotate several jars at one time to save horizontal

space.

|

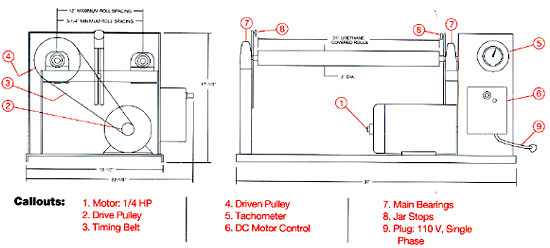

- Totally enclosed motors permit solid-state

control of roll speed

- Speed can be varied

- Rolls mounted in ball bearing pillow blocks.

- Rolls are made of long-wearing, oil, solvent

and chemical resistant Neoprene rubber

- Three-position lateral adjustment for roller.

- Lifetime lubricated and sealed ball bearing

pillow block

|

|

Options:

Revolution counters, automatic timers, motor controls,

explosion-proof motors. Options: Roll guard covers |

| |

|

|

|

| |

| |

|

|

| |

|

|

|

| |

|