|

|

|

| |

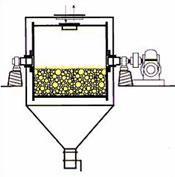

Batch

Type Ball Mills Batch

Type Ball Mills

|

|

| |

|

Batch operation minimizes

over grinding, resulting in improved milling efficiency,

lower specific power consumption and smaller mill

for given capacity.

Appropriate for relatively

small scale or intermittent operation where continuous

milling would be inappropriate. Batch Mills enable

extended and variable residence/grinding times

to be accommodated.

|

|

| |

- The mill has

fabricated steel shell with bolt-on fabricated

end plates incorporating shafts mounted in roller

bearings and driven through a direct coupled

gearbox.

- The shell is fitted

with the necessary charging/discharging doors

and in the case of dry milling a dust hood incorporating

discharge hopper is fitted, totally enclosing

the mill

- In this mill the

product is fed to a classifier for controlling

final product size. Oversize material is returned

from the classifier to the mill for further

reduction. These mills are capable of achieving

10 microns or finer with appropriate classifier.

|

|

| |

|

Combined Drying and Grinding: By introducing hot air

supply to the ball mill a limited drying capability

can be provided

|

| |

| Iron-free Grinding: For applications where metal contamination

of the product must be minimized; high density alumina,

ceramic or brick mill liners and grinding media are used

|

|

|

| |

|

|

| |

|

Model

|

Total Volume Ltrs

|

Output Volume Ltrs.

|

Main HP

|

Grinding media Kg

|

Wejght of machine Kg.

|

Area required

mm³

|

Space required m²

|

|

BM-2-2

|

170

|

75

|

3

|

375

|

600

|

1200×1600

|

3

|

|

BM-2.6-2.6

|

340

|

150

|

5

|

750

|

900

|

1800×2000

|

4

|

|

BM-3-3

|

585

|

260

|

7.5

|

1,300

|

1,400

|

1800×2200

|

5

|

|

BM-4-4

|

1,385

|

620

|

15

|

3,100

|

1,600

|

2000×2800

|

5.5

|

|

BM-4.6-4.6

|

1,950

|

900

|

25

|

5,400

|

2,400

|

2200×3000

|

6

|

|

BM-5-5

|

2,700

|

1,200

|

30

|

6,000

|

3,000

|

2400×3400

|

7

|

|

BM-6-6

|

4.65

|

2,100

|

60

|

10,500

|

3,800

|

2600×4600

|

8

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

| |

|

|

| |

|

|

| |

|

|

|

| |

|